Fiber-optic

hydrogen

sensors

Introduction:

The

Hydrogen sensor project of VU University Amsterdam is

part of the "Sustainable

hydrogen program" of ACTS.

Goal

of the project

is the development of

sensitive, selective and fast indicator materials for optical fiber

hydrogen sensors. These

coatings will

be based on the "switchable" metal-hydride materials discovered

at

the

condensed matter group of the VU. These "switchable mirrors" are based

on materials involving alloys of

rare

earths, magnesium and some transition metals, whose optical proportions

depend

drastically on the amount of absorbed hydrogen. Fiber optics

as read-out is

selected,

as it

is intrinsically explosion-safe and easy to implement in a multi-sensor

safety system.

Switchable

mirrors:

Rare-earth

or transition metal based Mg alloys undergo a

transition from metal to semiconductor when hydrogen is absorbed in the

lattice. As a result the alloy changes optically from reflective to

transparent

or in some cases to a light absorbing black state.

|

|

|

|

|

A

mirror consisting of a Mg70Ti30

thin film layer |

|

After

applying a hydrogen

containing gas the mirror changes into a light absorbing Mg70Ti30Hx

layer. |

Our

goal is to develop a "metal-hydride switchable

mirror" which

is used as a safety detector in a future hydrogen economy.

|

|

|

A

typical application for

(fiber-optic.) metal-hydride based sensors. Multiple

sensors could monitor optically the safety at several locations in a

hydrogen powered car. |

We

aim to

detect 10% of the lower explosion limit in air, (which is 4%) within

seconds

and with an optical change of a factor 10. The detector should allow

repeated

use.

Device

architecture:

Our

best

hydrogen detection material is Mg70Ti30.

This alloy forms

a strongly light absorbing metal-hydride when hydrogen exceeds the

equilibrium

hydrogenation pressure of 0.4 mbar. The ideal architecture of the

sensing layer

and its optical response is calculated from the dielectric constants of

the

used metals [1].

|

|

|

|

|

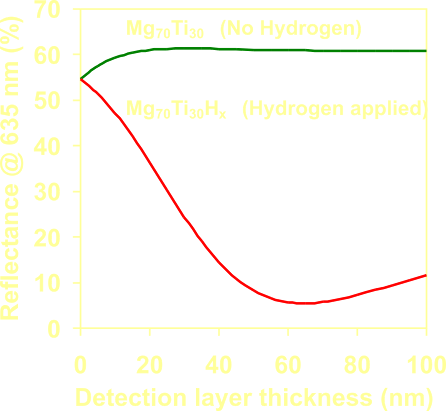

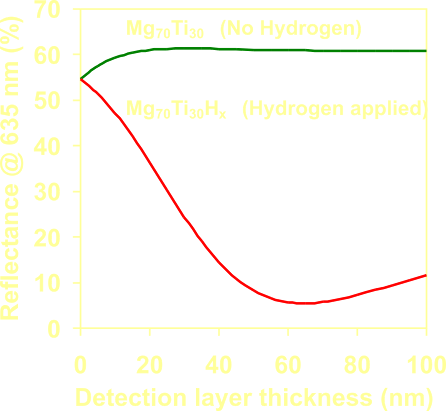

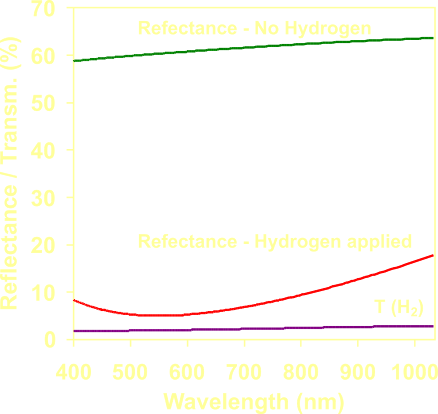

Calculated

effect of the layer

thickness on the optical response of the metal-hydride film (Mg70Ti30-Hx)

as a micro-mirror hydrogen detector. |

|

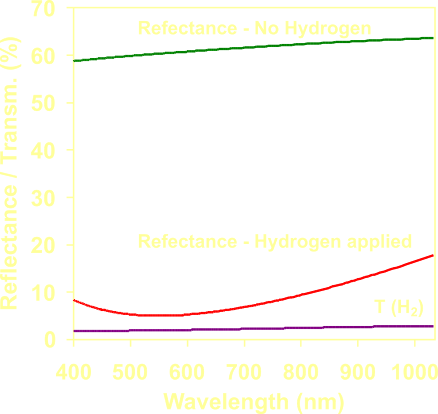

The

optical response vs

wavelength in the whole visible spectrum for a Mg70Ti30

layer of 60 nm, during hydrogen loading. |

The

Mg-Ti alloy

layer is covered by a 30 nm thick Pd layer which promotes the hydrogen

uptake

of the detector and prevents the layer from oxidation.

|

|

|

Typical

configuration of a fiber-optic micro-mirror hydrogen sensor,

based on a metal-hydride. The catalytic Pd layer can be

covered

with an extra protective coating. |

Device

preparation:

The

Mg-Ti

detection layer and the Pd cap layer are deposited on freshly cleaved

multi mode

glass fibers. By using glass fibers no electrical

leads are needed near the sensing point in a potentially explosive

environment. In a safety application multiple fiber detectors can be

read by a

single set of light source and detector. Deposition

of the layers is done by magnetron sputtering in argon. The composition

and

thickness are verified with a stylus profiler and Rutherford

Backscattering

Spectrometry.

|

|

|

|

|

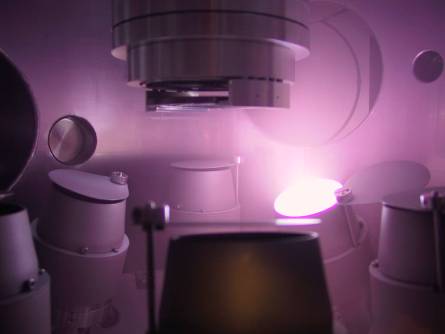

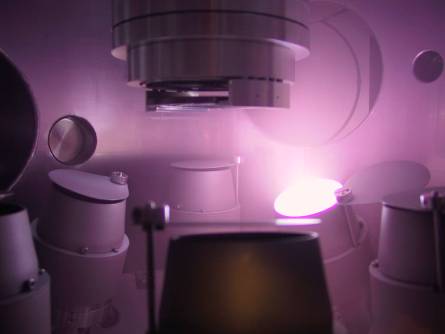

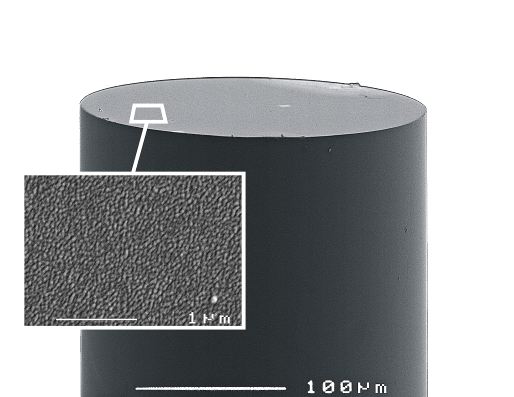

Argon-plasma magnetron

sputtering apparatus for depositing thin metal films on glass fibers

|

|

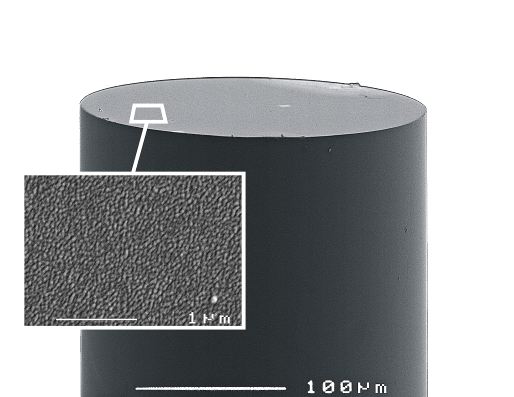

SEM image of a cleaved

end of a

glass fiber, after the deposition of the "switchable-mirror" layers.

|

Characterization:

We

connect the detector to a standard

bifurcating fiber which guides light from a white light source to the

indicator layer and guides the reflected light to a CCD

spectrometer. A low cost readout can be build from

a red LED, a CD-player beam splitter and a PIN diode.

|

|

|

|

|

Setup

for characterizing

the hydrogen detectors. Light is guided via a bifurcator to

the fiber end. The reflected light is measured by a CCD spectrometer.

The environment of the fiber end can be temperature controlled. |

|

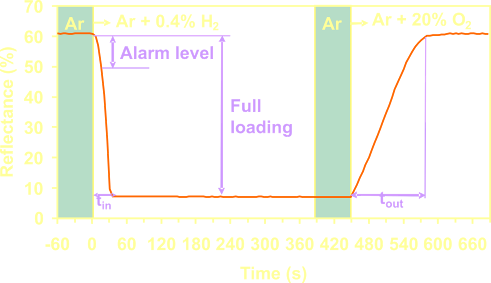

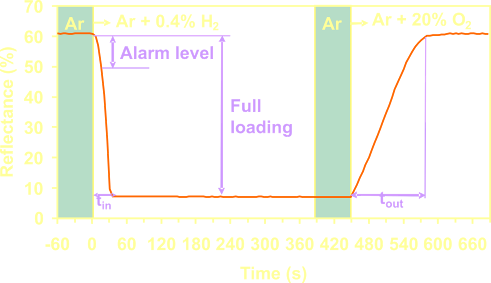

A

typical response of a Mg70Ti30

based detector. When a small concentration hydrogen is mixed

with the buffer gas (Argon) the reflection of the detector layer drops

by a factor 10 within seconds. |

The

detector

regenerates to its original state when the hydrogen

concentration drops below

the equilibrium pressure of the hydride. The unloading rate

of the detector increases when oxygen is present. The large

optical change upon hydrogen

loading allows the use of alarm levels in a hydrogen detector

application,

which improves the stability and reaction speed of the application.

|

|

|

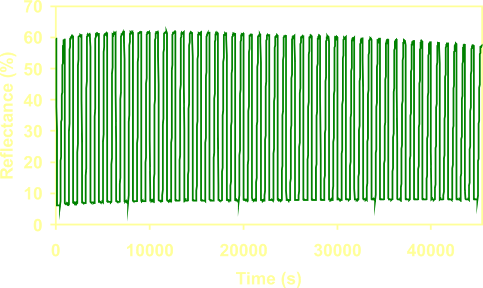

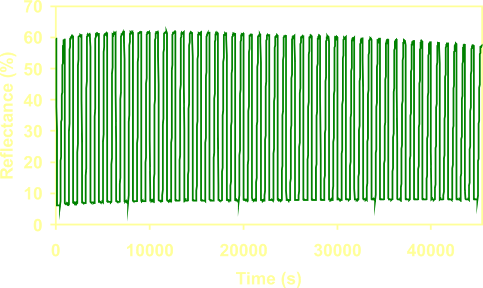

The

hydrogen detector

maintains its optical properties and reaction speed after many hydrogen

loading / unloading cycles. |

Over

100 stable cycles are measured, which

is more than enough for a

safety device. Oxidation of the detection layer due to cycling

stress can be reduced by using a thin NbOx

or AlOx

layer between the Pd

layer and the Mg70Ti30

layer.

Device improvements:

The

detection of low concentrations

hydrogen is within seconds.

The detector functions (unlike commercially available

detectors) well in oxygen poor

environments like argon glove boxes and over a large temperature range.

|

|

|

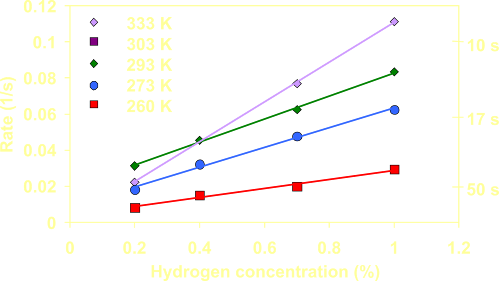

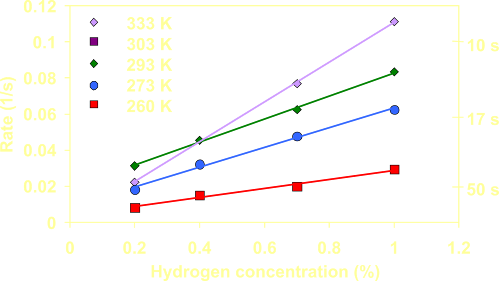

The

hydrogen detector is

characterized for low concentrations hydrogen in a broad temperature

range; it still operates below the freezing point of water. |

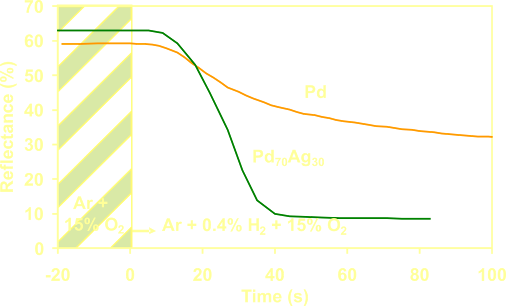

Oxygen

en carbon oxides in the environment of

the detector can lower the sensitivity and the kinetics due to

surface reactions on the catalytic Pd layer. These

effects are reduced by alloying the Pd layer with for example Ag [2]. A

hydrophobic organic coating on top of the Pd

layer prevents the detector from degradation by moist when

the detector is stored or used

for a long period in air.

|

|

|

|

|

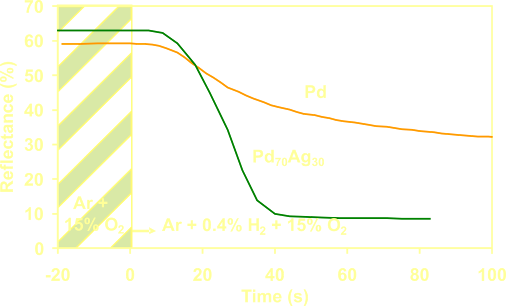

By

alloying the catalytic

Palladium layer with Silver it becomes less sensitive for oxygen and

carbon molecules on the surface of the detector. |

|

The

left side of the

mirror is coated with a hydrophobic coating, which prevents the metal

from degradation by the moist in the air. |

Prototypes:

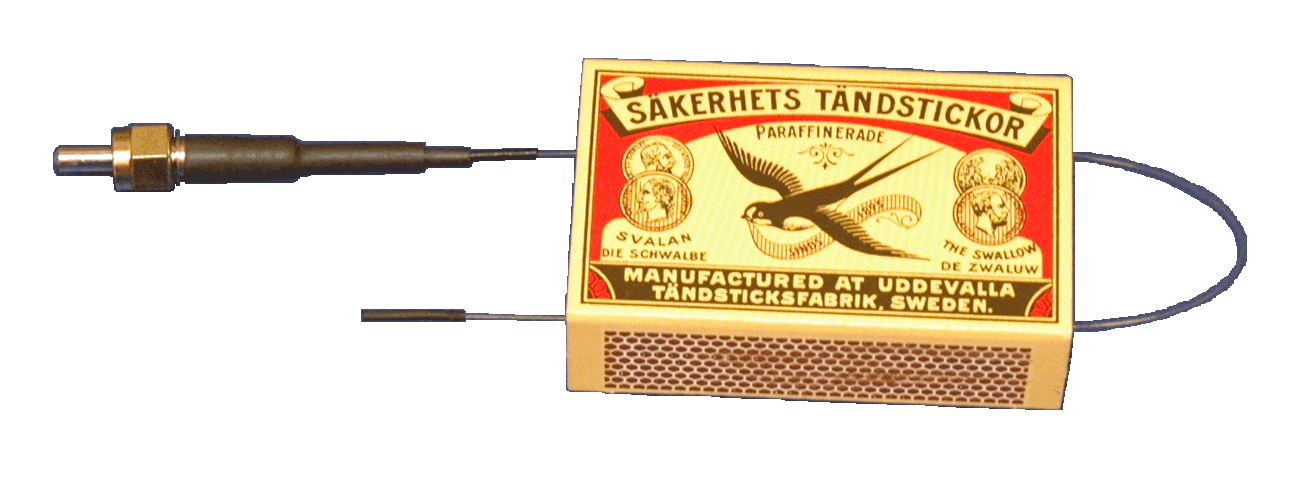

A

series of fiber optic hydrogen

detector prototypes

together with a

small readout system is currently spread among 10

hydrogen research laboratories in Europe. They

will test the

behaviour of the detector in a variety of conditions like in argon

glove

boxes or in polluted environments.

|

|

|

|

|

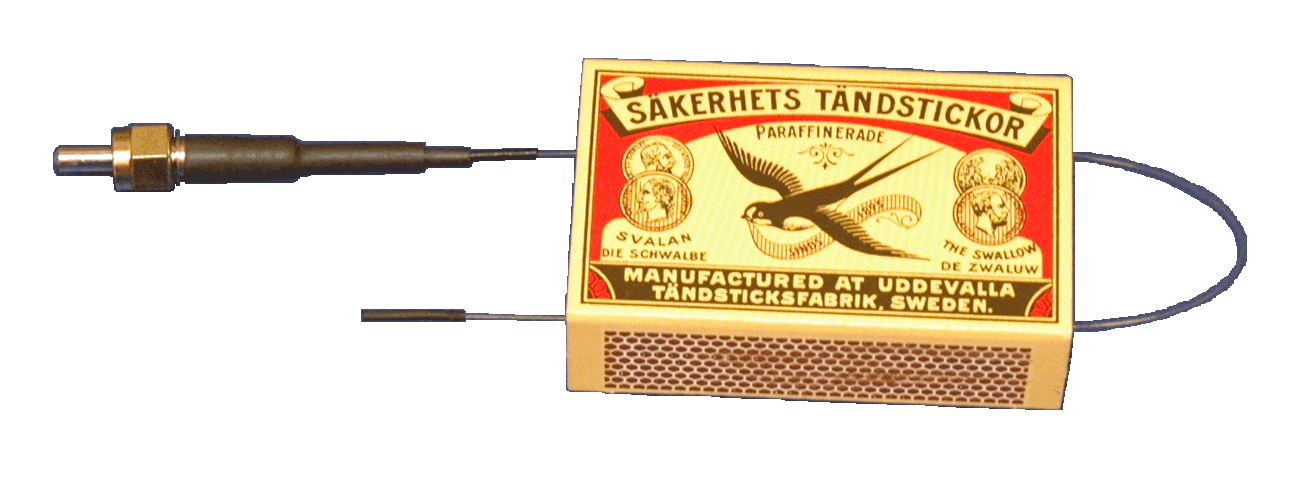

First

prototype of

the

fiber-optic hydrogen detector. |

|

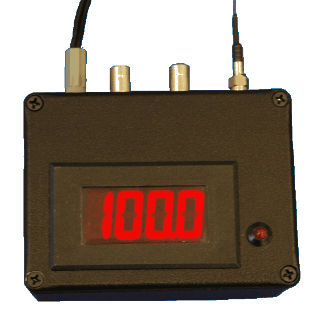

Readout

box for the field

test of the fiber-optic hydrogen detector. |

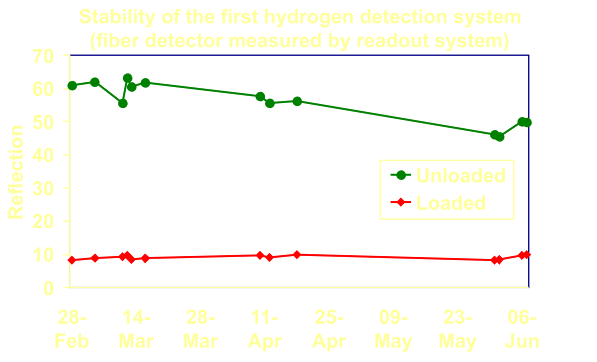

So

far we observe a reproducible

detection of pure hydrogen in air during a test period of several

months. Our

research will now focus on developing a sensor for quantitative reading

of the

hydrogen concentration in air.

|

|

|

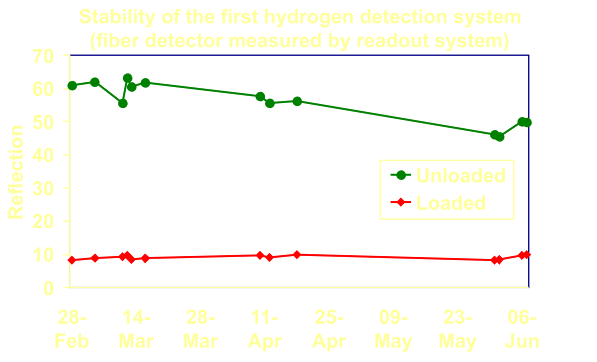

First

results of the metal-hydride based fiber-optic hydrogen detector field

test. The detector is tested for a period of months in air, several

times a small cloud of hydrogen was released near the fiber-end. The

drop in reflection in the unloaded state was caused by a drift in the

readout box. |

References:

[1].

M. Slaman, B. Dam, M. Pasturel, D.M. Borsa, H. Schreuders, J.H. Rector,

R. Griessen, Fiber

optic hydrogen

detectors containing Mg-based metal

hydrides, In press

by Sensors & Actuators B: chemical

123, Issue 1, 10 April 2007, Pages 538-545

[2]. M. Slaman, B. Dam,

H. Schreuders, R. Griessen, optimization

of Mg-based fiber optic

hydrogen detectors by alloying the catalyst,

Int. J. Hydrogen

energy 33

(2008) 1084-1089.

[3].

Patent: Protective

coating for metal-hydride based devices,

filed

in march 2006, Inventors: B. Dam, H. Schreuders, M. Slaman and M.

Pasturel (owned by ACTS); WO2007126313, NL1031708, (P6007119NL).

[4]. Patent: Optical

switching device, filed in

September 2005,

Inventors: B. Dam, R. Griessen, W. Lohstroh, M. Pasturel and

M. Slaman (owned by ACTS); WO2007049965, NL1030299, EP1952195,

CA2627651, AU2006306870, US2008291452, PCT/NL2006/050268 (P6003851NL).

Download A4

poster (.pdf) (900 KB)

Contact

Back